Catch issues early and with consistency

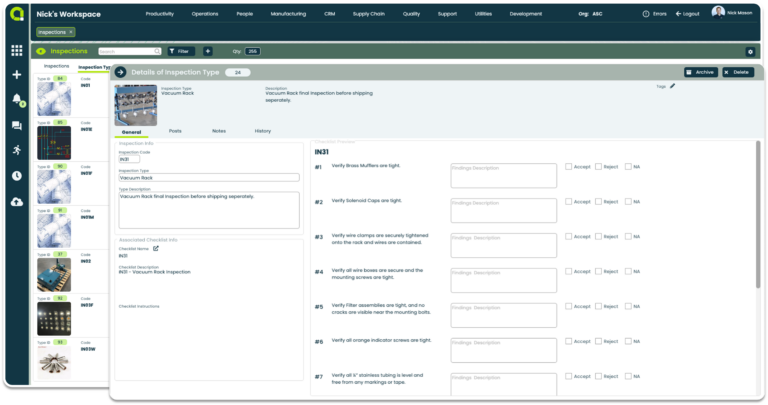

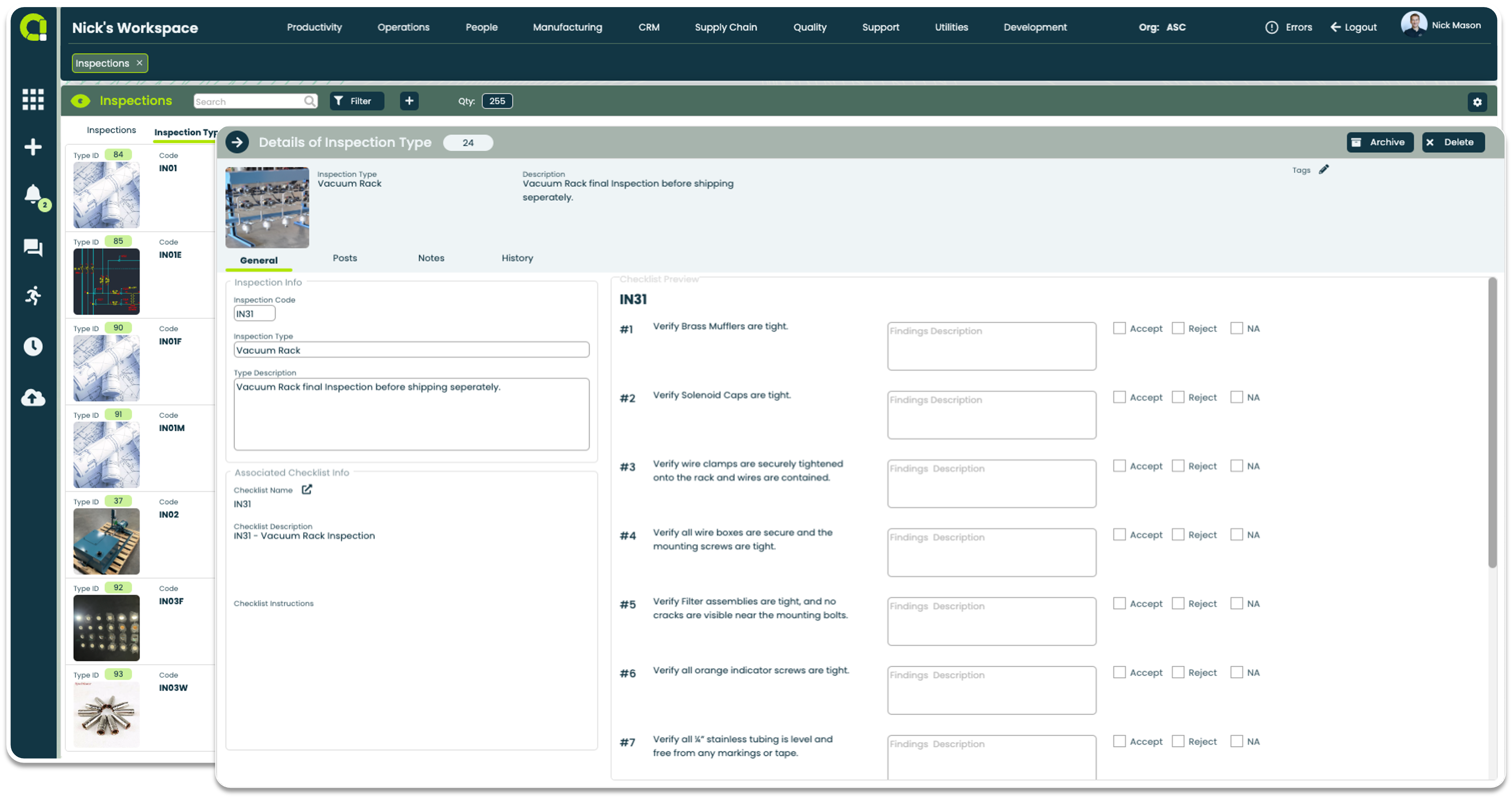

- Define inspection types with directions and checklists for specific products, parts and assets

- Reference specifications for Parts, Projects, and Drawings to ensure products and processes meet requirements and compliance with industry standards

Quality control built into your apps so you can build it into your culture

- Include Inspections in Appward Work Orders to ensure the highest quality output

- Create Inspections for use in Appward Receiving to asses all parts and products shipped to you

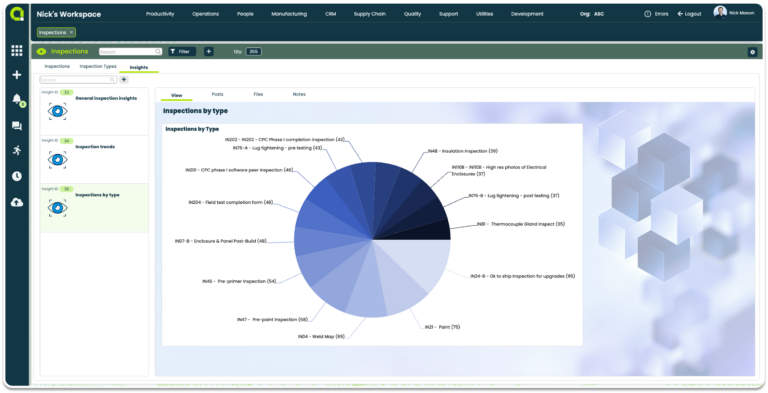

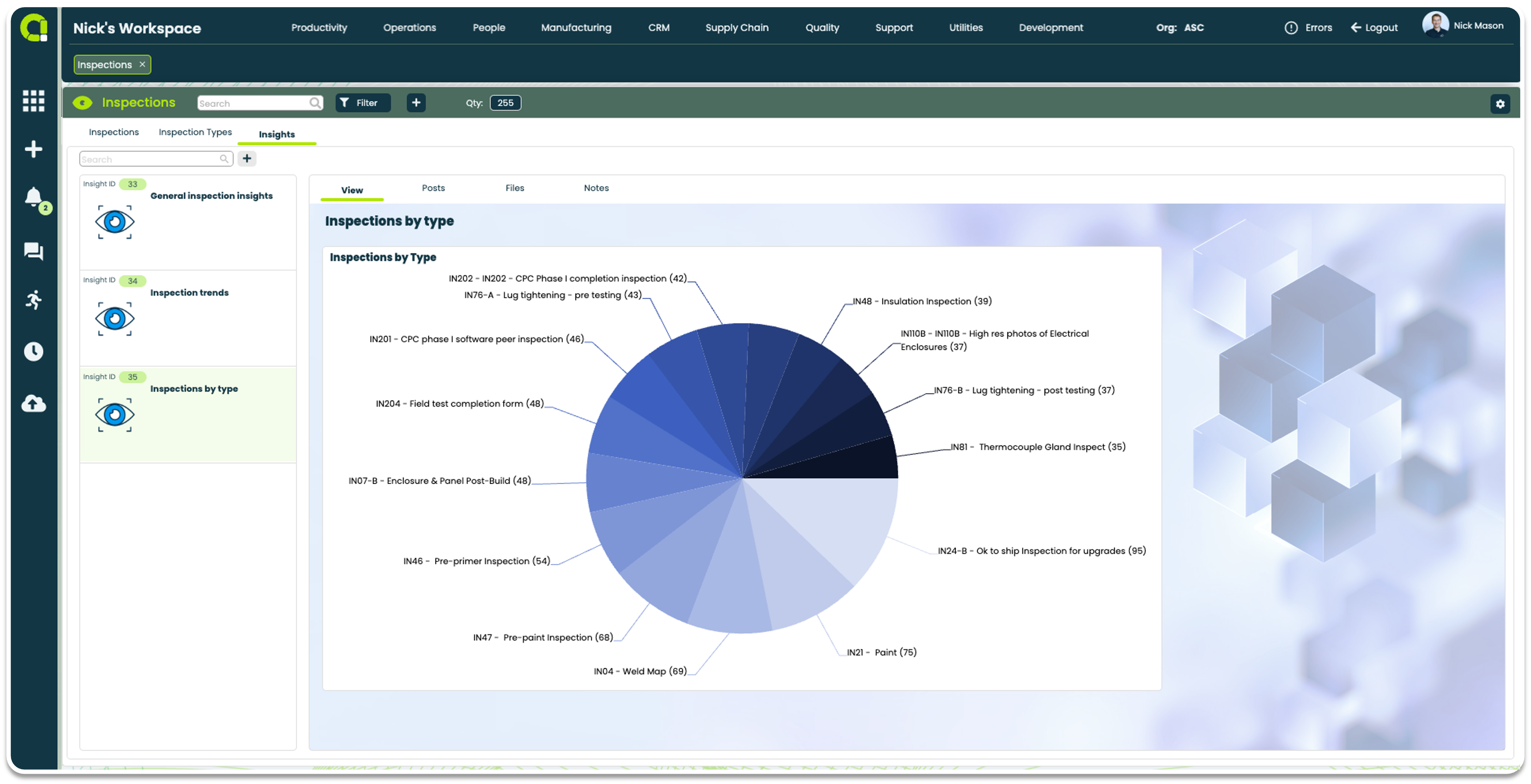

- Monitor trends with Insights to anticipate opportunities and failures

Inspections App Features

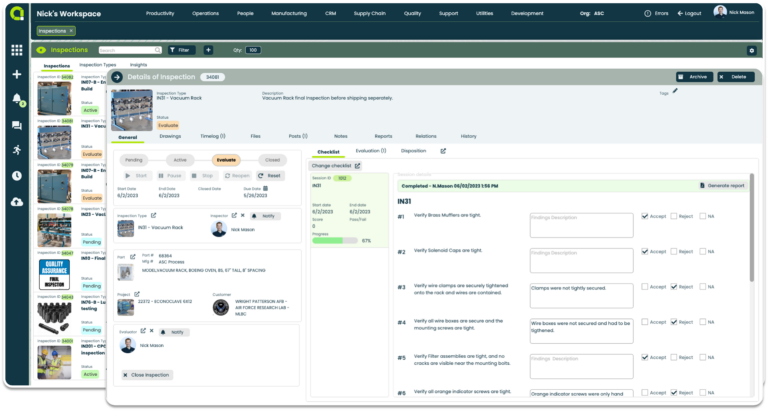

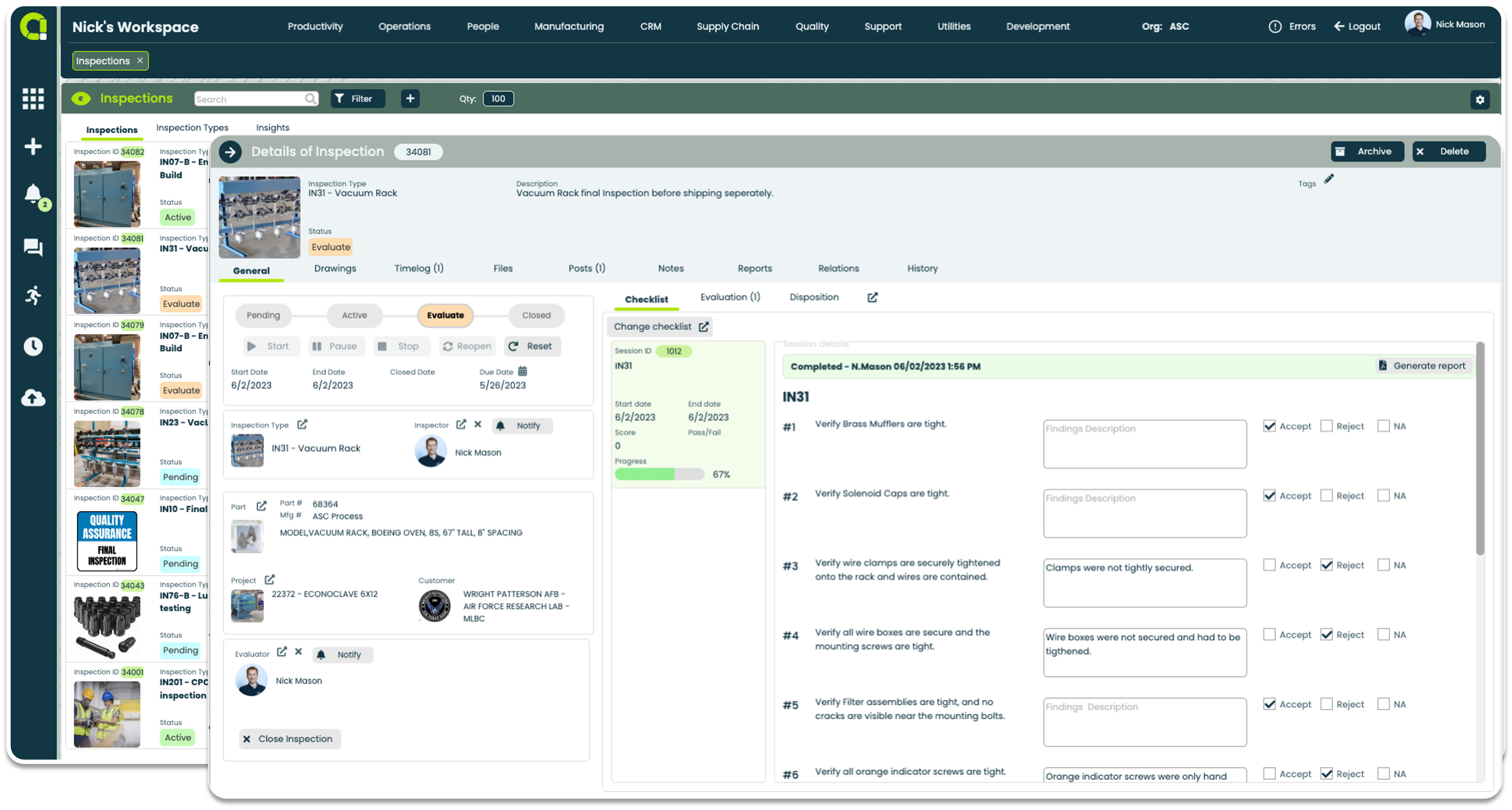

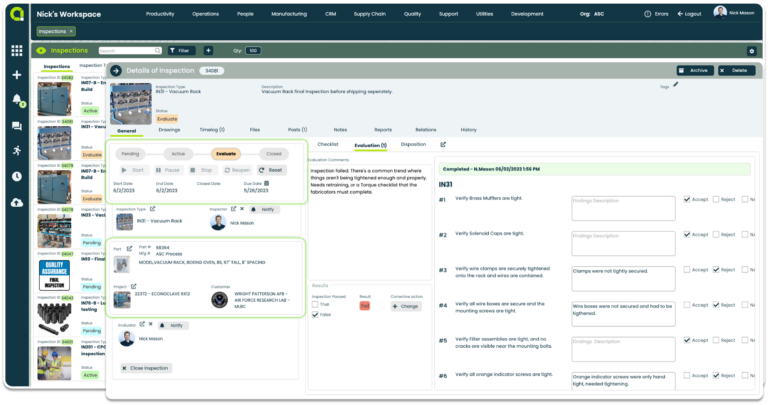

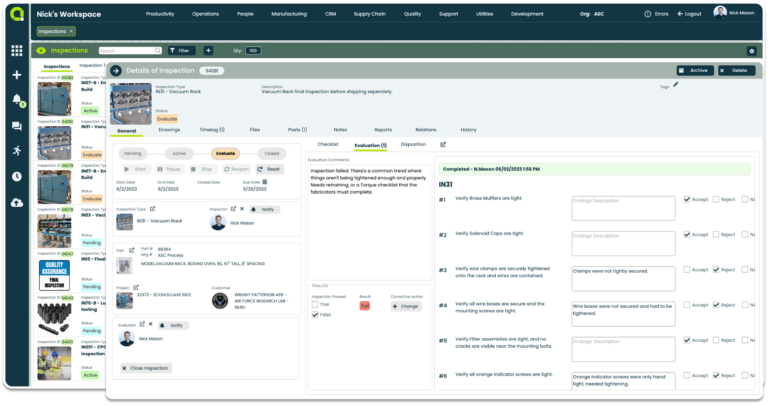

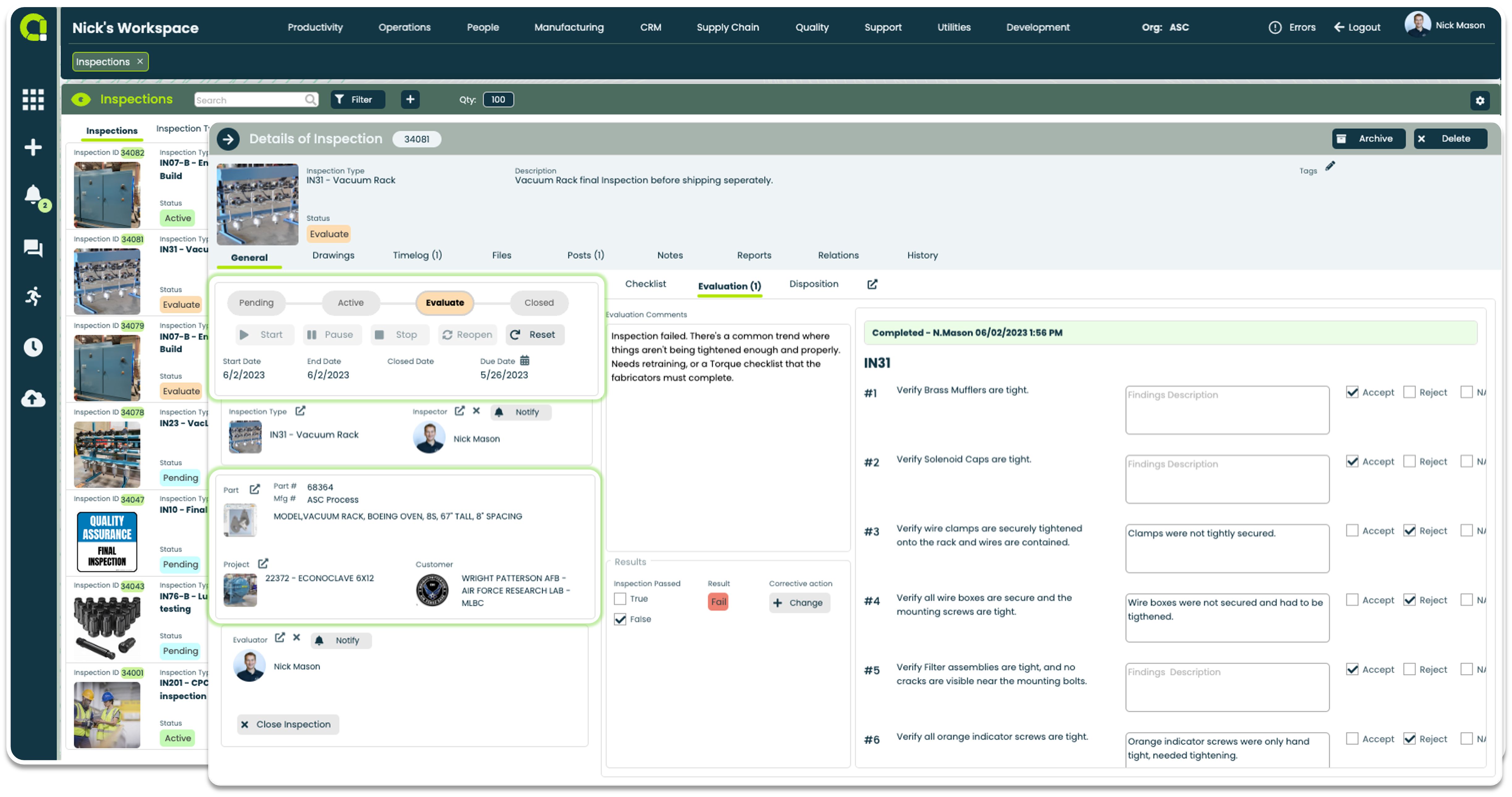

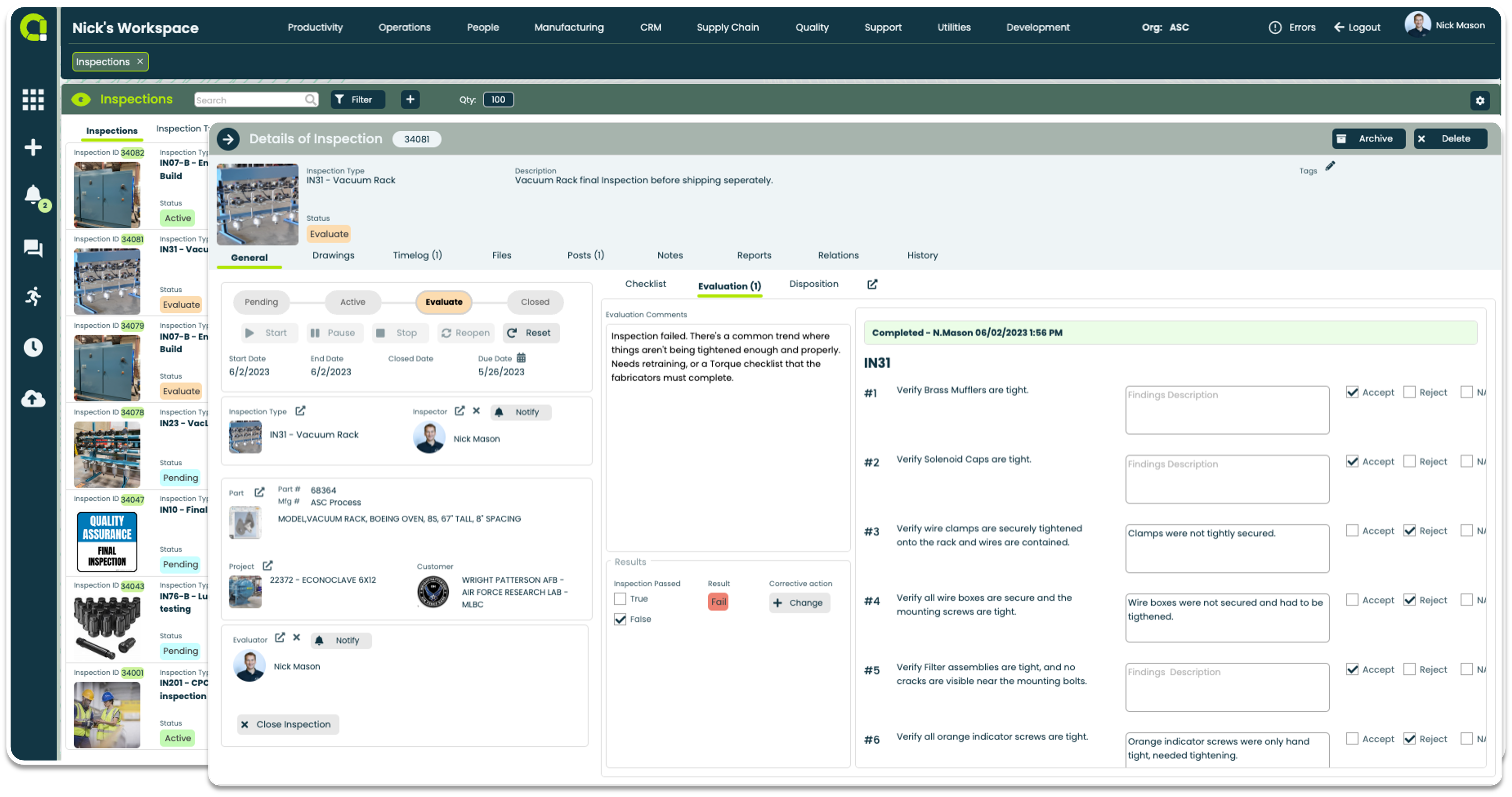

- Oversee all active inspections with instant access to inspection details

- Track inspection progress with a multi-stepped progress bar

- Identify inspection types and assigned inspectors

- Reach out to inspectors with a single click using the notify button

- Seamlessly link and manage Parts, Projects, Drawings and Customer details across the Appward platform associated with each inspection

- Assign evaluators for thorough assessments

- Manage existing checklists or add new ones to standardize inspections that need to meet certain criteria or regulations

- Access evaluation details; completed checklists, comments, and final results

- Link the progress of each associated checklist with the status of each inspection

- Set a start and end date for each checklist for accurate tracking

- Instantly view a checklist’s score and determine whether it passed or failed

- Begin and end checklists in a hassle-free manner

- Generate comprehensive reports to analyze performance

- Set up a multi-staged approval process with multiple participants or just a one-step approval to review inspection process

- Label each stage of your approval process and assign who you would like to approve within that part of your process

- Set a deadline date for each approver so they are aware of when they need to approve

- Add members for full visibility into all comments, feedback, posts and key information of a change request to make well-informed decisions

- Send notifications and reminders to each approver, letting them know they are part of the approval process or to submit their responses

- Discuss insights and get input from others in your organization in a dedicated forum

- Add @mentions to message others in your organization using Notification link in the Appward sidebar

- Like a post to acknowledge and notify the author

- Attach documents, images, media and AppShare links connecting to any record in Appward

- Attach files related to individual Insights to conveniently provide supporting information

- Link to files in the Appward Cloud, Appward Documents or upload from local storage

- Organize files by list order using arrow keys

- Gather metrics to identify patterns, recurring issues, or bottlenecks within inspections

- Analyze data to proactively address challenges, streamline processes, and drive continuous improvement

- Garner insights to understand inspection outcomes to maintain compliance and ensure you are meeting regulatory requirements

- Utilize metrics to track the status and progress of inspections

- Generate comprehensive reports to analyze inspection details

- Customize reports that provide an audit trail, showcasing a detailed history of inspection activities and changes made over time

- Export reports in various formats, including PDF and Excel

- Utilize reports to identify trends and areas of improvement

- Share reports with stakeholders for collaboration and decision-making

- Use the built-in timer to log time spent working on each part of the inspection process or as a whole

- Start, Pause and Stop buttons for automatic time stamps of dates and times

- List view of each time a team member has logged time working on an action; accessible in Outgoing and Incoming Tabs

- Quickly see a complete total of hours, minutes and seconds spent

Related apps

Inspections works seamlessly with Appward apps and services so you can do much more.

Related Posts